- Robotized station for gas chamfering – 1 pc

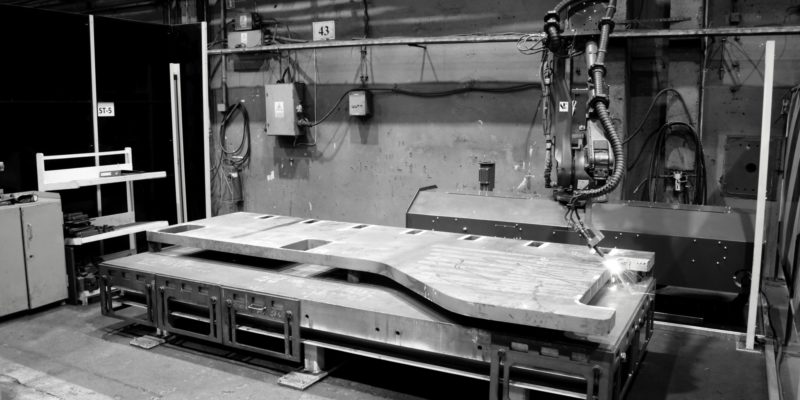

- CNC 3D Plasma Burner – 1 pc

- Chamfering Table – 3 pcs

- Oxy-gas burner – 3 tables, 4 burners each

- Hydraulic Press 360T – 1 pc, 140T – 1 pc

- Overhead Crane SWL 8 pcs (20T – 1 pc, 10T – 2 pcs, 8T – 1pc, 5T – 4pcs)

- Jib Crane SWL – 19 pcs (2T -7pcs, 1T – 6psc, 0,5T – 6 pcs)

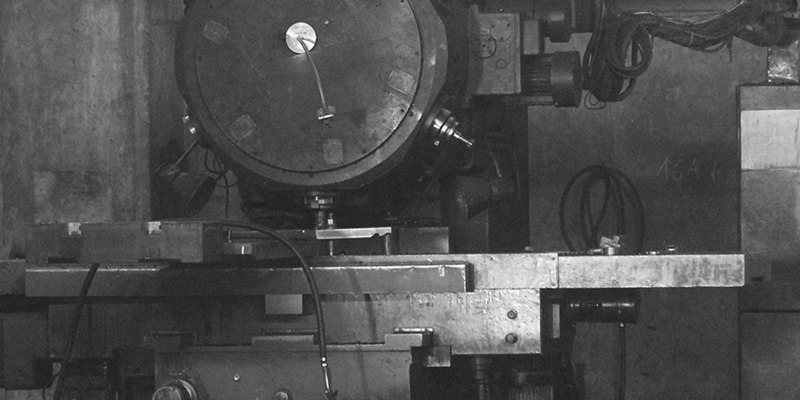

- Boring Machine – 3 pcs

- Milling Machine – 8 pcs

- Semi-automatic Welding Machines Essamig Aristo U-5000, EWM PHOENIC 401 – 40 pcs

Moreover:

Production Registration System – providing continuous monitoring of production process for both efficiency and quality.

Quality Control Equipment – weld gauges, ultrasonic defect detector Krautkramer USM35, electromagnets, UV lamps.

Robotized station for gas chamfering

x – 5400, y – 2000

Big Boring Machine

x – 4000, y – 2000, z – 1000

Small Boring Machine

x – 1900, y – 1200, z – 1000

CNC 3D Plasma Burner

CNC Oxy-Gas Burner

table 3500 x 30000

MAG Welding Machine

Milling Machine

Band Saw

Drilling Machine

Lathe

Chamfering Table

Hydraulic Press

360T

Hydraulic Press

140T

Overhead Crane

SWL – 20T, hak H – 6m

Overhead Crane

5T

Jib Cranes

5T

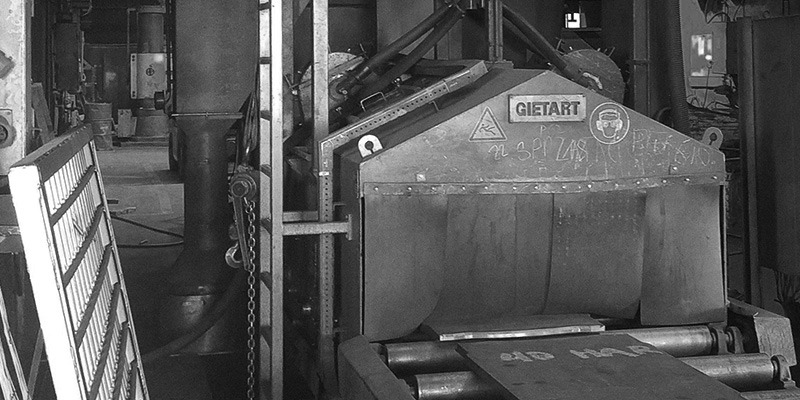

Shot-blasting machine

Possibilities:

- 220 technical workers

- 40 welding stands

- 15 assembly stands

- 4 production halls

- 6000 m2 of total area

- 6000 tonnes of steel structures per year

- repair of mining power cables